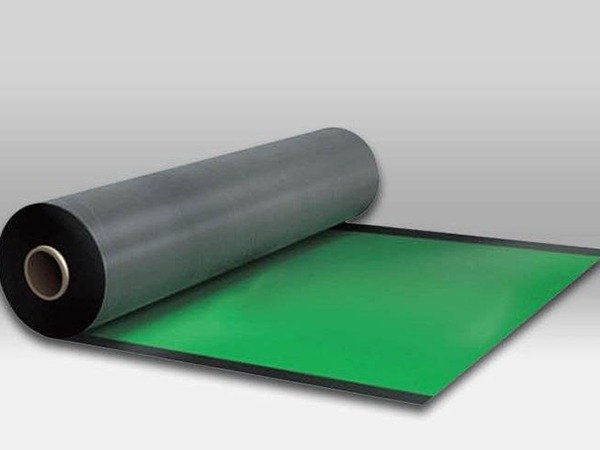

Self-adhesive waterproof membrane

描述

product description:

Self-adhesive rubber asphalt waterproofing membrane is a self-adhesive waterproofing material based on elastomers such as SBS and asphalt, with polyethylene film, aluminum foil as surface material or no film (double-sided self-adhesive), and an anti-adhesive isolation layer. Self-adhesive rubber asphalt waterproofing membrane is a new type of building waterproofing material with broad development prospects. It has excellent water impermeability, low temperature flexibility, extensibility and adhesion. In particular, it has self-healing properties, which is an advantage that ordinary waterproof materials do not have, and can ensure the super waterproof quality of waterproofing projects.

No adhesive is needed, just peel off the isolation layer and it can be firmly bonded to the base layer. Easy to construct and extremely fast.

It has the elasticity of rubber and excellent elongation, and can well adapt to the deformation and cracking of the base layer.

It has excellent adhesion to the base layer, and the adhesion force is often greater than its shear force. It can be bonded with concrete, rubber, plastic, metal, and wood.

It has self-healing properties, that is, when the membrane is punctured or embedded with hard objects, it will automatically heal with these objects and still maintain good waterproof performance.

The construction is safe, does not pollute the environment, the construction is simple, and it is easy to achieve civilized construction on site.

In addition to the main body material, the surface material polyethylene film also has excellent waterproofness and high strength (polyethylene polypropylene membrane is only waterproof with this film), so it has double insurance for waterproofing.

Corrosion resistance: This membrane has good resistance to acid, alkali and chemical corrosion, and has excellent aging resistance in various environments.

The super strong bonding performance between rolls and rolls ensures a tight, reliable and seamless overlap.

Scope of application:

It is suitable for waterproofing of roofs, basements, swimming pools, reservoirs, municipal projects and subway tunnels of industrial and civil buildings. It is also suitable for waterproofing projects of wooden and metal structure roofs. It is especially suitable for waterproofing projects such as petroleum depots, chemical plants, textile factories, and grain depots where open flames are not suitable.

It is divided into three types based on different surface materials: PE (polyethylene surface) is suitable for non-exposed waterproofing projects; AL (aluminum foil surface) is suitable for exposed waterproofing projects; N (no film, that is, double-sided self-adhesive) is suitable for auxiliary Waterproofing project; used in combination with polymer waterproofing membrane; divided into exposed waterproofing project (O) and non-exposed waterproofing project according to the use function.

Specifications and area: 20m2, 10m2, 5m2 width 920mm, 1000mm thickness 1.2mm, 1.5mm, 2.0mm.

Construction application:

1. Base layer requirements: The waterproof layer should be solid and smooth, without hollowing, looseness, sanding, peeling, dust, debris, oil stains, rust, etc. The moisture content of the base layer should be less than 9%.

2. Node treatment: Use self-adhesive membranes to make additional layers for special parts such as eaves corners, gutters, wall corners, drain openings, and deformation joints.

3. Brush or spray the special base treatment agent. After the base treatment agent dries, the roll material can be laid.

4. Overlap width: The overlap width of the long and short sides is 80mm.

5. Horizontal paving: First use an ink line to pop up a baseline on the base layer, and then pave from low to high. While unrolling the roll, uncover the isolation paper and pave along the baseline. Immediately after paving, use a rubber roller to press [ Reality.

6. Vertical surface paving: Pave the vertical surface from low to high, unfold the isolation paper while unfolding it, and compact it with a rubber roller after paving.

7. Closing of the coil: The closing area is sealed with sealant, and then fixed with metal strips. The fixing screws and the top seam must be sealed.

8. Membrane-free waterproofing membranes are used in composite construction with our company’s polymer membranes.

9. Waterproof protective layer: The protective layer should be made according to the provisions of “Technical Specifications for Roofing Engineering”.